Automotive SPICE Capability Levels Explained

Automotive SPICE Capability Levels Explained

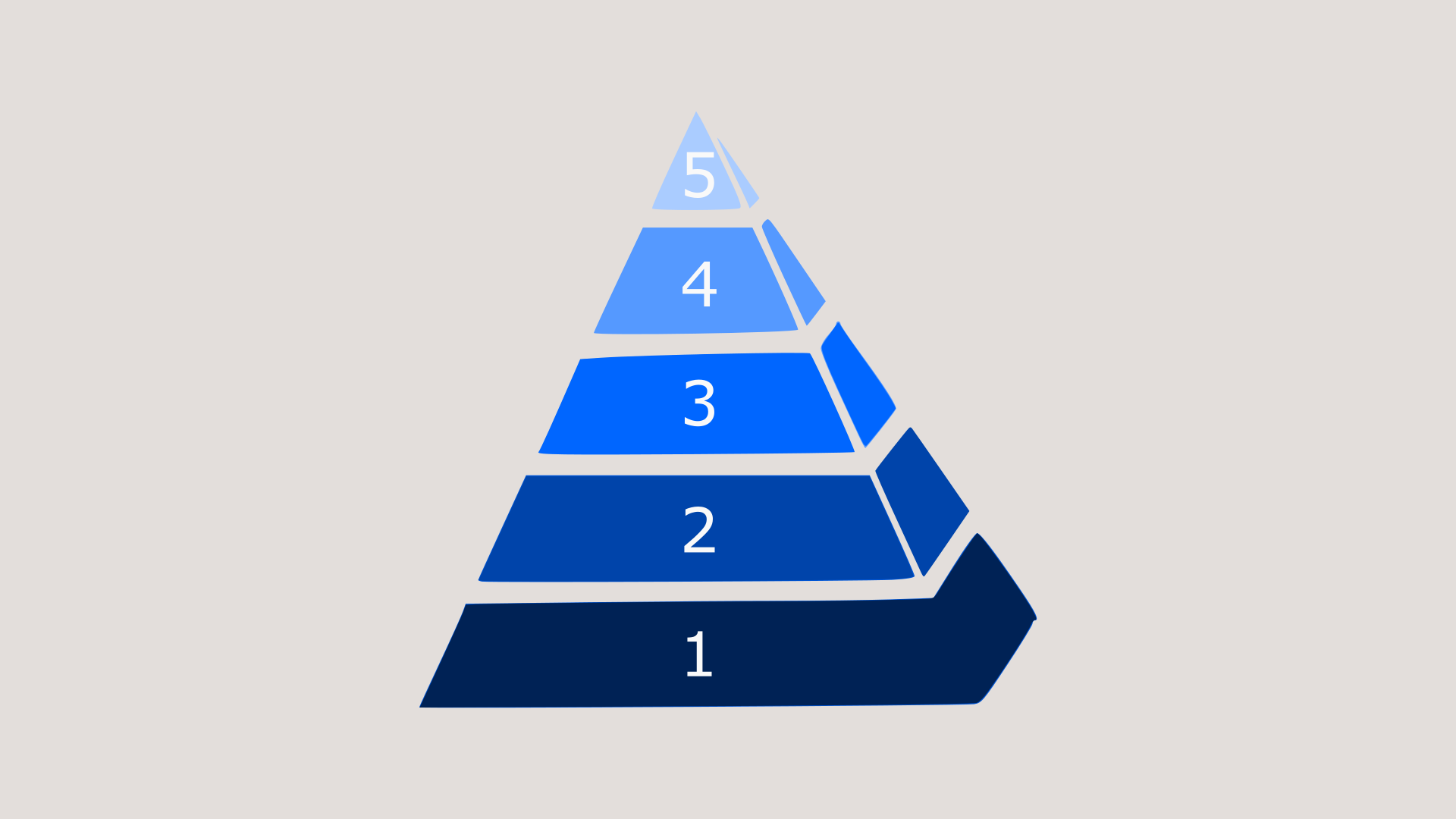

Automotive SPICE (ASPICE) helps development teams measure how well their processes produce reliable software and electronic systems. It organizes process maturity into six capability levels. Here’s a plain‑language look at what each level means and why it matters.

Level 0 – Incomplete

A process at level 0 is missing important steps or outputs. Work may start, but it doesn’t consistently achieve the intended result. There might be no clear plan, little documentation, and unpredictable outcomes. Teams at this level struggle to build repeatable quality because everyone tackles tasks differently and lessons aren’t shared.

Level 1 – Performed

At level 1 a process actually accomplishes its purpose. The team follows basic steps and delivers identifiable work products. However, the approach can still vary from project to project. There is limited tracking or management oversight. You do get the job done, but success often depends on the individual skills of the engineers rather than a controlled process.

Level 2 – Managed

A managed process builds on level 1 by introducing planning and control. Work is scheduled, responsibilities are clear, and the necessary resources are provided. Teams monitor progress and keep records of the outputs. Management ensures the process happens consistently, not just when a particular engineer is available. This brings predictable results and provides a foundation for improvement.

Level 3 – Defined

Here the organization has a standard process that is tailored for each project. Roles, activities, and quality criteria are described in detail. Training and reusable templates help everyone work the same way. Because the process is defined, teams can compare results across projects and share best practices more easily. This reduces surprises and improves collaboration with suppliers.

Level 4 – Quantitatively Managed

A level 4 process is measured and controlled using objective data. Teams collect metrics on things like defects, timing, or effort. They analyze this information to understand performance trends and predict outcomes. With data in hand, management can make informed decisions about risks and efficiency. Deviations from the plan are addressed quickly because they are visible in the numbers.

Level 5 – Optimizing

At the highest level, the organization uses the data and lessons from previous projects to continuously enhance the process. Improvements are not ad‑hoc; they are planned and evaluated for effectiveness. Teams experiment with new methods and automation, always looking for ways to prevent issues before they arise. The goal is sustained excellence and the ability to adapt as technology and business needs change.

In short, Automotive SPICE capability levels describe a path from unpredictable work to a culture of ongoing improvement. Moving up the levels helps automotive projects deliver safer, more reliable systems while controlling cost and schedule.